Application Of Inertia Cone Crusher In Su石灰石rhard Material Crushing

.jpg)

Minerals Free FullText A Dynamic Model of Inertia

2020年9月29日 It is a very powerful method for a dynamic model of an inertia cone crusher containing particles based on the coupling of 2021年2月4日 In this paper, the process of crushing steel slag is taken as a specific research object, to analyze the influence of two mass variables on the inertia cone (PDF) Influence of Two Mass Variables on Inertia Cone Crusher In this paper, the process of crushing steel slag is taken as a specific research object, to analyze the influence of two mass variables on the inertia cone crusher performance A Influence of Two Mass Variables on Inertia Cone Crusher 2021年8月15日 DEMbased models of cone crushers are gaining attention in the literature (Quist, 2012); however, their applications are limited to predicting the crusher A review of modeling and control strategies for cone crushers in

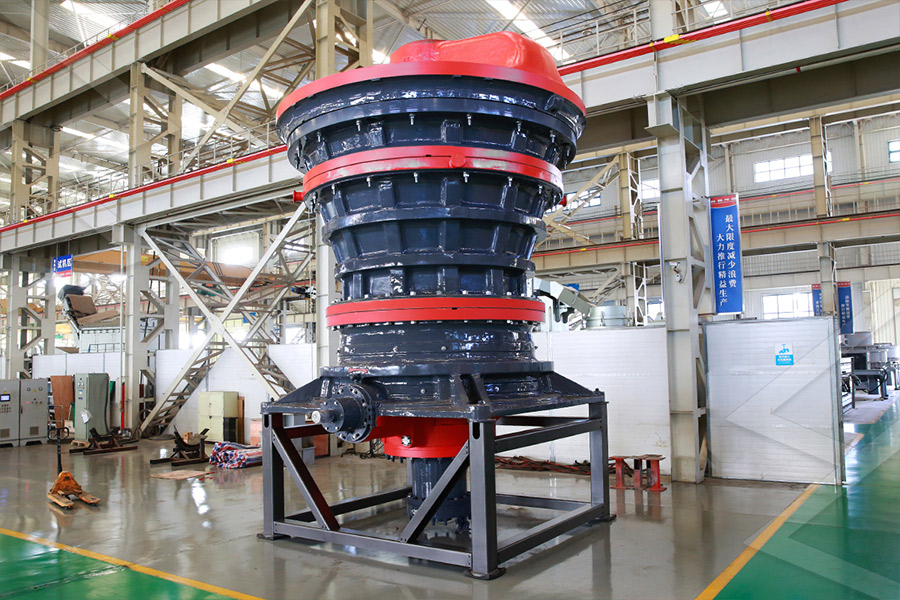

Application and Development of Inertia Cone Crusher in China

2018年1月1日 Inertial cone crusher is like a maverick flower in the field of crusher With its excellent performance and excellent application effect, it shocks the world and is Inertia cone crusher is a highefficiency superfine crushing equipmentwith the advantages of bigger reduction ratio, lower overcommimintion ratio and lower unitenergy WET APPLICATION OF INERTIA CONE CRUSHER惯性圆锥破碎机是一种具有独特原理和结构的新型节能超细破碎设备,能实现物料的选择性破碎,满足“多碎少磨”新工艺的要求该机不仅破碎比大,产品粒度细而均匀,而且单位电耗低, 惯性圆锥破碎机在金属矿山的研究应用APPLICATION OF The purpose of this paper is to focus the application of reliability centered maintenance with an aim to improve the reliability of the cone crusher reliability tools failure modes and Reliability centered maintenance of cone crusher: a case study

Inertia Machine Freeport, IL Crushing and Screening Equipment

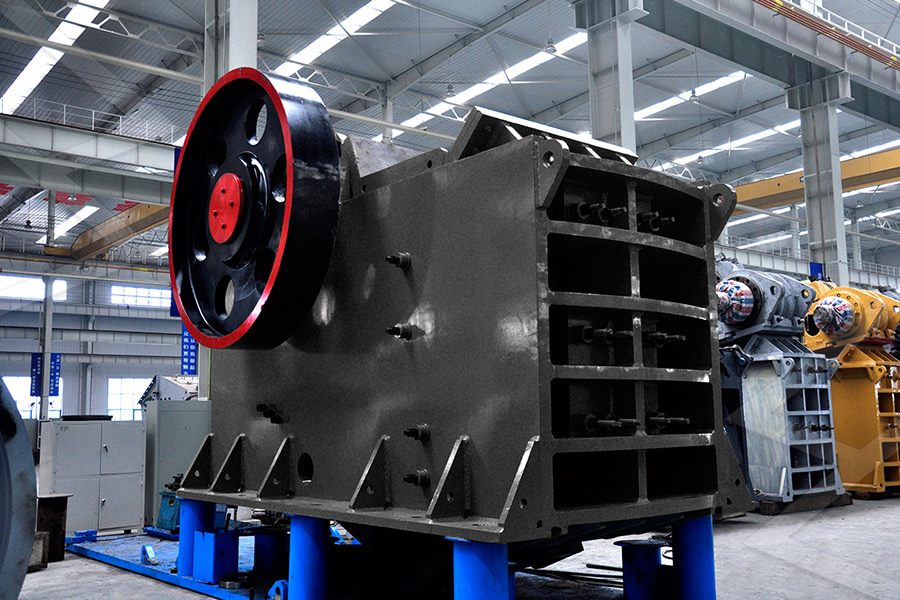

Inertia Machine has a great variety of portable aggregate crushers and screening equipment They are great for a variety of jobs like quarrying, recycling and demolition projects We are conveniently located in Freeport, IL visit us today!2017年1月1日 The relative breakage points are t 2 for the percentage of progeny finer than half of the parent particle size and t 4 for the percentage of progeny finer than one quarter of the parent particle size and so on The resulting graph consists of a series of smoothly increasing curves and one straight line which is t 10 plotted against itself This map, Analysis of cone crusher performance with changes in material 2023年7月31日 A cone crusher is crucial, especially in aggregates and mining industries It plays a role in crushing hard rocks into smaller rocks for further processing Understanding how a cone crusher operates is essential to optimize its performance to achieve effective crushing This article will delve into the components of the cone How Does A Cone Crusher Work: Understanding The Crushing 2023年2月21日 Crushing Process in a Jaw Crusher The crushing process in a jaw crusher begins with the feeding of the material into the crushing chamber The material is crushed between a fixed jaw and a moving jaw, which moves back and forth against the fixed jaw The material is crushed by the compressive force generated by the movement The Ultimate Guide to Jaw Crushing Machines: Types More Tips

Comparative Analysis of Blow Bar for Different Crusher Applications

2024年6月25日 Advantages: Long lifespan in highimpact applications Disadvantages: Susceptible to rapid wear when crushing less abrasive materials Martensitic Steel: Characteristics: Good wear resistance and impact strength, with moderate hardness Applications: Ideal for recycling applications and crushing mediumhard materials like 2017年1月31日 In compressive crushing machines (eg, jaw crusher [3], cone crusher [4]), the material could be broken into coarse particles mainly resulting from the induced tensile failure, and fines mainly Analysis of cone crusher performance with changes in material 2023年2月15日 Jaw crushers are commonly used in the mining and aggregate industry for breaking down different types of materials, such as rocks and minerals, into smaller pieces There are several types of jaw crushers available in the market, each with different capabilities and specifications In this article, we will discuss the most common types of A Guide to Types of Jaw Crushers for Crushing Rocks and Minerals2021年3月25日 They handle medium hard to very hard, abrasive materials that can be dry or wet but not sticky Cone Crushers are typically found in quarried materials and sand and gravel applications They provide a reduction ratio of 3:1 to 5:1 Material that enters a Cone Crusher is compressed between a wobbling mantle and the concaves inside the What Type of Crusher Is Best for Primary Crushing? McLanahan

Moment Of Inertia Of A Cone Complete List Of Formulas And

Moment of inertia of a cone can be expressed using different formulas depending on the structure of the cone We have to take into account two main types – hollow and solid cones Solid Cone For a solid cone the moment of inertia is found by using the given formula; I = 3MR 2 / 10 Hollow Cone For a hollow cone, we determine the moment of 2023年2月22日 Tooth roll crusher finds its application in various industries that require material reduction Some of the common applications include: Mining and quarrying: Tooth roll crushers are used to reduce the size of minerals Tooth Roll Crusher: A Versatile Equipment for Material Reduction 2020年9月29日 The cone crusher plays a vital role in mineral processing, which has been used widely in medium and fine crushing stages in mineral processing comminution operations []As a variant of the cone crusher, Minerals Free FullText A Dynamic Model of Inertia 2020年9月29日 This thesis presents a methodology that enables the modelling and simulation of dynamically interacting belt models in Discrete Element Method (DEM) simulations(PDF) A Dynamic Model of Inertia Cone Crusher Using the

.jpg)

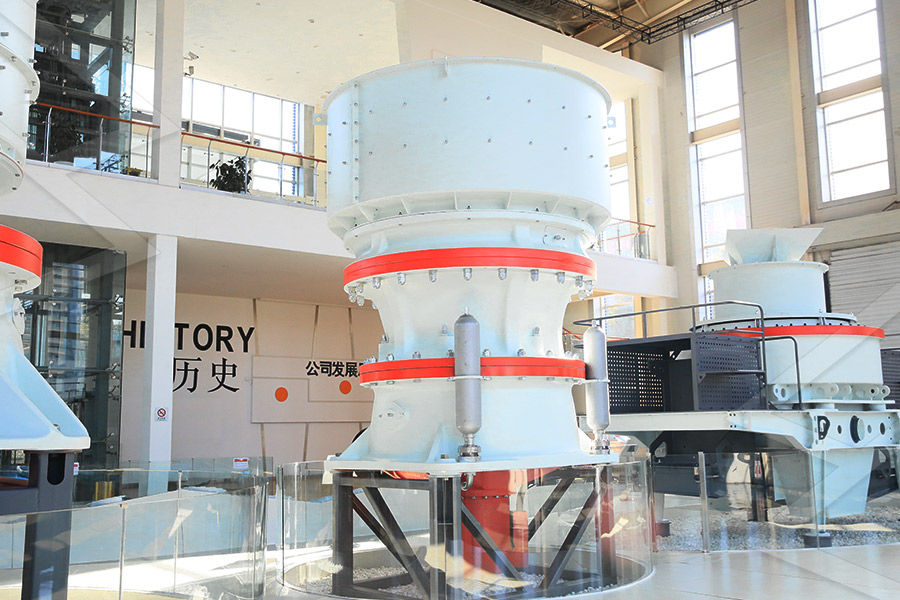

Types of Crushers: What You Need to Know HUATAO GROUP

2023年8月2日 Material from a cone crusher can be used for lots of different projects including road base on construction projects, asphalt pavement resurfacing, or in gravel pits for road construction Cone crushers are suitable for mediumhard and hard materials like virgin rock from quarries Cone crusher cross section Roller crushers2024年7月17日 Cone Crusher Cone crushers utilize lamination crushing, where material enters the crushing chamber from the top and is compressed and ground into smaller particles between calcite, marble, iron ore, and granite, providing sand and gravel aggregates for roads, construction, and cement applications Compound Crusher The Types of Crushers: Choosing the Right One for Each StageCone Crusher History The cone crusher was first developed in United States in the 1920’s by Symons Brothers of Milwaukee Symon Brothers are credited as the first designers and inventors of the spring cone crusher The Symons Brothers cone crusher’s biggest advantage was its durability and simplicity (the entireCone Crushers (Parts of a Cone Crusher) Explained saVRee2020年6月15日 Cone crushers are commonly used in medium and fine crushing operations, and can crush a variety of ores and rocks with Platts hardness f≤516 and above Cone crusher is widely used in mining The Application of Cone Crusher LinkedIn

Understanding the Cone Crusher Working Principle

2023年2月21日 If you're in the market for a cone crusher, it's important to understand the machine's working principle to make an informed decision In this comprehensive guide, we'll explain the working principle of a cone crusher, its components, maintenance tips, benefits, and offer practical advice on how to choose the right cone crusher for your application2023年2月28日 Learn about the different types of secondary crushers, including impact crushers, cone crushers, roll crushers, and jaw crushers, and their functions, advantages, disadvantages, applications, and factors to consider when selecting them Discover case studies and examples of successful applications, as well as future developments in A Comprehensive Guide to Secondary Crusher TypesSepro Mineral Systems’ new Blackhawk 100 cone crusher for heavyduty crushing applications incorporates advanced technology with affordability to provide a reliable and simpletooperate crushing solution, offering a combination of speed and 100 kW of power for fine crushing capability and high capacity in a compact design The Blackhawk 100 Affordable Cone Crusher for Heavyduty Applications E MJ2023年2月15日 It is similar to the standard cone crusher, but with a larger crushing chamber and a higher power rating The mediumsized cone crusher is often used in the mining and aggregate industries for crushing large volumes of material Short Head Cone Crusher The short head cone crusher is designed for tertiary and quaternary crushing A Comprehensive Guide to Cone Crusher Types

Evaluation of size reduction process for rock aggregates in cone crusher

2020年6月4日 The size reduction process of rocks in cone crushers is one of the most important issues, particularly for the secondary and tertiary stages of crushing operations In this study, 17 different rock types were considered for the evaluation of their size reduction variations that occurred in a laboratoryscale cone crusher Based on several 1 – outer cone, 2 – inner cone, 3 – inner cone support bearing, 4 – crusher frame, 5 – inner cone shaft, 6 – eccentric mass, 7 – belt transmission, 8 – support spring, 9 – spring Examples of vibratory crushers applications in crushingquaternary stage applications for fine crushing and may be in closed circuit returning to the crusher Liners are manufactured from XT510™, XT520™, XT525™, XT710™, XT750™ or XT770™ material depending on the application and material characteristics 1 The minimum setting is that at which the crusher will operateApplication guide Nordberg® MP Series™ cone crusher wear pa2021年2月4日 In this paper, the process of crushing steel slag is taken as a specific research object, to analyze the influence of two mass variables on the inertia cone crusher performance(PDF) Influence of Two Mass Variables on Inertia Cone Crusher

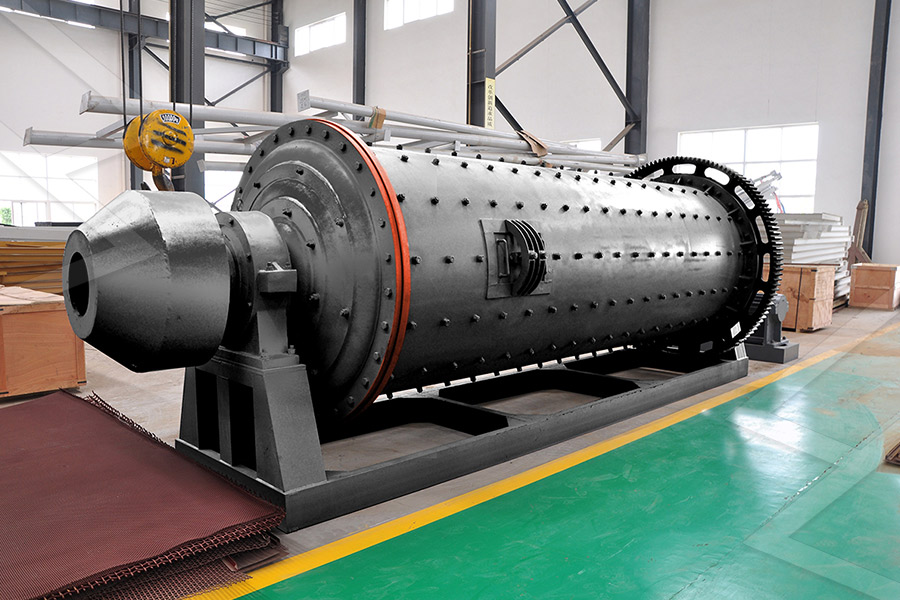

A Guide to Mobile Crushing Plants: Types, Components, Applications

2023年2月24日 Mobile crushing plants have revolutionized the way materials are extracted and processed in various industries They offer flexibility, mobility, and efficiency that cannot be achieved with traditional stationary crushing plants As the name suggests, these plants are designed to be easily moved from one site to another, making them 2008年8月1日 12 Production challenges in miningIn a typical mining application, a primary crusher reduces the size of blasted rock; from several hundred mm down to 0–250 mm A secondary crusher then reduces the size from those 250 mm down to about 0–70 mm, and is then followed by a tertiary crusher in closed circuit with a screenThe final Energy considerations in compressive and impact crushing of rockMinerals 2021, 11, 163 3 of 18 eccentric vibrator (B3); O4 is a planar joint between B3 and B4; O5 is a ballpin joint between B3 and the connecting shaft (B5); O6 is a universal joint between B5 and the drive shaft (B6); O7 is a revolute joint between B6 and the ground (B0) Figure 1 Schematics of the inertia cone crusher: (a) vertical crosssection and (b) Influence of Two Mass Variables on Inertia Cone Crusher 2023年2月22日 Description: This article provides a comprehensive guide to understanding the different parts of cone crushers, their functions, and the importance of proper maintenance It covers various types of cone crusher parts, common issues and solutions, and future developments in the industry Whether you are in the market for a new cone Understanding Cone Crusher Parts Names, Functions, and

.jpg)

Understanding Industrial Crushers: Types And Applications

2023年8月1日 Cone crushers; The cone crusher features a coneshaped crushing surface This unique shape allows it to perform a distinct crushing action that is essential in many industrial applications A cone crusher squeezes the material between an eccentrically gyrating spindle and a concave hopper2021年4月16日 A measure of the size reduction achieved for a particular crusher application is the reduction ratio A cone crusher in a secondary crushing application will typically work with a 35:1 to 5:1 reduction ratio Tertiary cone crusher configurations typically work with a reduction ratio of 25:1 to 4:1The pros and cons of cone crusher applications Quarry2024年3月19日 The crushing shell has a fixed cone (bowl liner) and a moving cone (inner crushing cone or mantle) They form the crushing chamber The eccentric shaft is made from manganese steel alloy It’s powered by the crusher’s motor It rotates in a special way, making the mantle move back and forth This crushes the material against the bowl linerCone Crusher Diagram: Simplified Guide JXSCDSMAC Jaw Crusher Features Based on principle of crushing without rubbing Minimum dust Oil lubrication, Law wear parts Gap adjustment and overload protection High capacity, High operational eliability Long Jaw Crusher: Range, Working Principle, Application

Cone Crushers Crushing Equipment Minyu Machinery Corp

2023年8月7日 Usually, a cone crusher is installed in a crushing circuit as a secondary crusher Precrushed material fed in via the top of the cone crusher flows over the mantle while the vertical cone crusher drive shaft rotates the mantle The mantle performs eccentric movements under the concave (also called bowl liner), so squeezing 2023年12月1日 Section snippets Bonded particle model in DEM Simulations were performed by a commercial software EDEM (Ver 20222) In DEM, the governing equations for translational motion and rotational motion of each particle can be expressed according to Newton’s second law: m p d ν p d t = F p + m p g I p d ω p d t = T p where I p and m p Crushing characteristics and performance evaluation of iron ore in 2019年4月18日 Crushing is a size reduction process that plays a key role in both mineral processing and crushing–screening plant design Investigations on rock crushability have become an important issue in An experimental investigation on rock crushability using jaw and cone tigation of High Speed Cone Crushing Using Laboratory Scale Experiments and DEM , Published in proceedings of the 14th European Symposium on ComminutionandClassification(ESCC2015),p 193199,2015Applications of Dynamic Modeling in Crushing Plants Chalmers

How Does a Cone Crusher Work and What is It? JXSC

2024年3月15日 The crushing cone’s axis experiences a powerful swing when the eccentric sleeve rotates Importantly, this swinging movement causes the crushing wall’s surface to move in a way that continually approaches and recedes from the rolling mortar wall’s surface The cone crusher operates on the basis of this dynamic action2023年1月1日 Inertia cone crushers are widely used in complex ore mineral processing The two mass variables (fixed cone mass and moving cone mass) affect the dynamic performance of the inertia cone crusherCrushing characteristics and performance evaluation of iron ore in 2020年6月3日 In this Cone Crusher article we want to educate you about what to consider when purchasing a cone crusher It also will inform and educate you if you are a current owner or operator of a Cone Crusher If you have a good base of knowledge about cone crushers you can skip through the article by choosing the topics belowWe will be A Detailed Overview of Cone Crushers and What You Need to ZI Cone Crusher – in stock now If you are wanting to increase plant capacity and improve product shape, the ZI Cone Crusher Series delivers EarthTechnica, the crushing equipment division of Kawasaki Heavy Industries, have developed the ZIseries cone crusher to incorporate all the key benefits of the successful Kawasaki CYBAS Cone Impact, Cone Jaw Crusher Equipment For Sale Kobe Kawasaki

.jpg)

Inertia Machine Freeport, IL Crushing and Screening Equipment

Inertia Machine has a great variety of portable aggregate crushers and screening equipment They are great for a variety of jobs like quarrying, recycling and demolition projects We are conveniently located in Freeport, IL visit us today!2017年1月1日 The relative breakage points are t 2 for the percentage of progeny finer than half of the parent particle size and t 4 for the percentage of progeny finer than one quarter of the parent particle size and so on The resulting graph consists of a series of smoothly increasing curves and one straight line which is t 10 plotted against itself This map, Analysis of cone crusher performance with changes in material 2023年7月31日 A cone crusher is crucial, especially in aggregates and mining industries It plays a role in crushing hard rocks into smaller rocks for further processing Understanding how a cone crusher operates is essential to optimize its performance to achieve effective crushing This article will delve into the components of the cone How Does A Cone Crusher Work: Understanding The Crushing 2023年2月21日 Discover everything you need to know about jaw crushing machines, from the various types such as single and double toggle, hydraulic and portable models, to their working principles, advantages, and disadvantages This comprehensive guide also provides expert tips on maintenance and selecting the right machine for your specific applicationThe Ultimate Guide to Jaw Crushing Machines: Types More Tips

.jpg)

Comparative Analysis of Blow Bar for Different Crusher Applications

2024年6月25日 Advantages: Long lifespan in highimpact applications Disadvantages: Susceptible to rapid wear when crushing less abrasive materials Martensitic Steel: Characteristics: Good wear resistance and impact strength, with moderate hardness Applications: Ideal for recycling applications and crushing mediumhard materials like 2017年1月31日 Request PDF Analysis of cone crusher performance with changes in material properties and operating conditions using DEM Discrete Element Method (DEM) simulation with nonround particles and Analysis of cone crusher performance with changes in material 2023年2月15日 Jaw crushers are commonly used in the mining and aggregate industry for breaking down different types of materials, such as rocks and minerals, into smaller pieces There are several types of jaw crushers available in the market, each with different capabilities and specifications In this article, we will discuss the most common types of A Guide to Types of Jaw Crushers for Crushing Rocks and Minerals2021年3月25日 They handle medium hard to very hard, abrasive materials that can be dry or wet but not sticky Cone Crushers are typically found in quarried materials and sand and gravel applications They provide a reduction ratio of 3:1 to 5:1 Material that enters a Cone Crusher is compressed between a wobbling mantle and the concaves inside the What Type of Crusher Is Best for Primary Crushing? McLanahan

.jpg)

Moment Of Inertia Of A Cone Complete List Of Formulas And

Moment of inertia of a cone can be expressed using different formulas depending on the structure of the cone We have to take into account two main types – hollow and solid cones Solid Cone For a solid cone the moment of inertia is found by using the given formula; I = 3MR 2 / 10 Hollow Cone For a hollow cone, we determine the moment of 2023年2月22日 Tooth roll crusher finds its application in various industries that require material reduction Some of the common applications include: Mining and quarrying: Tooth roll crushers are used to reduce the size of minerals Tooth Roll Crusher: A Versatile Equipment for Material Reduction